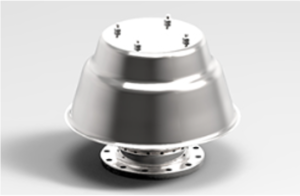

Flame Arrester

The deflagration flame arrester is symmetrical and offers bidirectional flame transmission protection. The number of Flame Elements and their gap size depends on the arrester’s intended use.

Specifying the operating conditions, such as the temperature, pressure, explosion group, and the composition of the fluid, enables MF21

to select the best deflagration flame arrester for your application Our deflagration flame arresters is available for substances of explosion groups IIA and IIC (NEC groups D and C (MESG & 0.5 mm.

0.5mm ≥ MESG)). EN ISO 16852 / API 2000

Description

A flame arrester functions by absorbing the heat from a flame front traveling at subsonic velocities, thus dropping the burning gas/air mixture below its auto-ignition temperature; consequently, the flame cannot survive. The heat is absorbed through channels (passages) designed into an element. These channels are chosen and measured as the MESG (maximum experimental safe gap) of the gas for a particular installation On a fuel storage vent, flame arresters also serve a secondary purpose of allowing air pressure to equalize inside the tank when fuel is added or removed, while also preventing insects from flying or crawling into the vent piping and fouling the fuel in the tanks and pipes.

In-line / End-line type & also Detonation type is available.

Benefits

- Bi-directional flame transmission proof design

- Lowest pressure drop results in low operating and life cycle costs

- Protects with deflagrations for explosion groups IIA & IIB (NEC groups D & C)

- Optimized flow capacity

- Easier cleaning

Specification

| Size | From 1″ (ND 25A) To 40-in (ND 1000A) |

| MESG | less than 0.5mm To higher than 0.9mm |

Materials

| No. | Description | Spec.1 | Spec.2 | Spec.3 |

|---|---|---|---|---|

| 1 | Body | A216-WCB | A351-CF8M | B26-319 |

| 2 | Element Ring | A240-304 | A240-316 | A240-304 |

| 3 | Element Pad | A240-304 | A240-316 | A240-304 |

| 4 | Element | A240-316 | A240-316 | A240-316 |

| 5 | Lug | A240-304 | A240-316 | A240-304 |

– Special materials can available upon request.

English

English

한국어

한국어